The future of logistics is here and waiting to be deployed. Automation is the key to the establishment of a “connected supply chain”. As the current pandemic has taught us, we must be prepared for an autonomous future. With the potential for disruptions in the supplier and production networks due to any conditions from weather related phenomena, health related scares, and even market volatility, industrial manufacturers must be read for change. The best way to get there is to utilize all the perks of Industry 4.0 and optimizing the existing processes.

All fields are evolving, including supply chain fields. As an operational focus that is becoming simultaneously easy from the customer perspective, and more complex from the data processing perspective, there are various things that organizations will have to factor into their operations with each iteration of their supply chain and its integrated systems. Digitization is everywhere, and the key to modern digitization of supply chains is to ensure that each of the critical focuses and technologies are implemented where possible.

Lean organization is the key to industrial success. The ability to minimize waste and optimize resource utilization is the key to efficiency in a manufacturing and supply chain system. What life has taught us all in 2020 is the importance of organizations to keep an agile supply chain.

What is The Agile Supply Chain?

The agile supply chain is a very responsive system that adapts to the current environment that the manufacturing organization is operating in. The organization has the ability to scale up production, or scale down production as it sees fit. Where possible, it can also shift from batch to continuous production in order to meet its organizational needs and customer demands. The ability to be flexible is very critical in today’s manufacturing environment.

The agile supply chain is a real-time system that adapts its operating regime according to the supply and demand requirements that are fed to the system. As Just In Time operation, the operational system is leveraged in order to match the demand. With inventory minimization as the order of the present and future, it will be important for organizations to learn how to keep the inventory low, and to keep the production activities on a consistent flow.

The overstock of inventory is something that will affect an organization, and via lean the inventory management activities have been mastered. Agile systems are the ones that we need to adapt now to manage what we have in stock. Supply chain management practices are continuously optimizing such agile systems and keep their inventory levels low, with minimal disruptions to their operational plans. Delivery times were also well managed with the agile system.

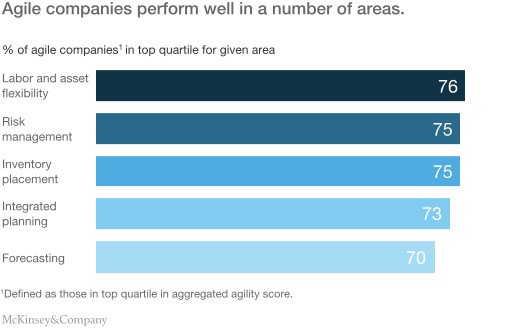

According to McKinsey and Company, the visual below highlights the areas that agile optimized their systems.

With an agile system that is always iterating and adjusting, there are also financial gains to be made in the form of operational savings. Via the utilization of cobots for instance, an organization will be able to utilize their robots to manage system orders.

As a system that adapts to parameters such as the economy, customer quality requirements, supply demands and cost requirements, the agile supply chain is where the industry is advancing. Responsiveness is key at uncertain times, and knowing how best to manage your system will be key to ensuring that the supply chain remains robust.

Supply Chain Optimization

Supply Chain Optimization is enabled via Agile Supply Chain Practices. When agile supply chain solutions are integrated into the process ideally close to the end product, the benefits are gained. From an inventory management level, the day to day analysis of the resource utilization can be tracked, and a forecast of order placement and order timing can be established.

Additional System Integrations

SELF DRIVING TRUCKS

In the wake of automation, self driving trucks are the future of freight. With various companies in the process of developing such technologies, eventually we will reach a stage in process optimization where driverless trucks will bridge the gap between suppliers and customers. With higher efficiency and reduced costs, companies that ship freight, can improve their bottom line.

Supply chains are very complex mechanisms that facilitate the distribution of items from a supplier to its customer base. With various interconnected elements in the transportation network, there must be some element of synchronicity between the involved parties. When determining how to engage all the different elements of the supply chain members such as suppliers, logistics service providers, freight forwarders and other critical process partners must be in the communication loop.

Communication in the supply chain is critical to ensuring that there is transparency in the supply chain. In the current global regime where fluctuations exist in the market demand, having key operational plans will be the way that organizations will be able to thrive. Just In Time Operations will no longer be a pipe dream, it will have to be a reality. Having a clear understanding of how the production forecast will be, will ensure that there is an appropriate operational, tactical and even strategic plan in place. With an autonomous supply chain in progress, the relevant systems can communicate with each other, and ensure smooth operations. Process transparency has to be a top priority to ensure success in the supply chain management.