All you need to know about six sigma and its benefits for you and your company.

So what is six sigma anyway?

In most cases Six Sigma is a method to measure process quality with the end goal of near-total perfection. The goal of using Six Sigma is to improve the end product (what a surprise!) by removing errors in the production process in any sphere where it’s applicable. It’s mostly a data-driven approach that relies on management strategies for improving process flow and end results.

The philosophy is simple – to work smarter, not harder. Decisions are based on data, process capability is improved, mistakes are reduced if not eliminated, sigma rating goes up.

This is achieved by creating select groups of trained and certified professionals within any given organization that would adopt, control and improve the Six Sigma methodology.

Each unique project within a given organization that would utilize the Six Sigma concept is going to have a very rigid set or rules for costs involved and expected end results.

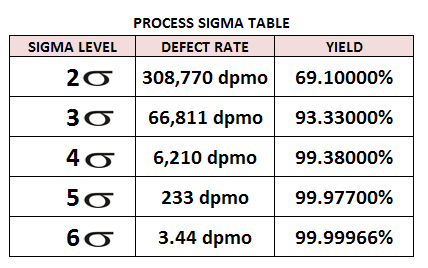

The term itself (Six Sigma) comes from manufacturing jargon and without going into specifics and technical details you should just remember that it refers to a process that has only 3.4 defects in a million output units (six sigma calculator) – be it physical products or other particular tasks that can be measured in units:

The Six Sigma Levels and their corresponding defects

A brief history of six sigma – not too thorough, not too boring.

The concept was first introduced in Motorola somewhere in the 70’s of last century. It was after a serious critique of the bad quality that senior executive Art Sundry was forced to do something about it. That’s how the six sigma concept started it’s slow introduction. A connection between quality improvement and cost reduction was found and things went off from there. Later in 1986 the concept was officially formulated and it’s been getting more popular ever since.

Now, an important argument that many Six Sigma believers sometimes omit is that the concept isn’t something revolutionary new. It didn’t just come out of nowhere – similar concepts did exist prior to the formulation of six sigma and they all do share common ground.

For example making the process less variable would result in more stable end results. Analysis is also an important and common element to all quality control and improvement movements. And in the end of the day it should be used all across the organization not just by discrete elements of it.

Six sigma methods

There are two methods used:

DMAIC (duh-may-ick) – Defining the problem, Measuring important aspects, Analyzing the information flow, Improving and Controlling.

DMADV (duh-mad-vee) – Defining goals, Measuring Critical to Quality CTQs characteristics, Analyzing, Designing details, Verifying.

As said above one of the important characteristics of Six Sigma is that it’s used all across the organization. Unlike most of the previous systems for quality management and control that were used only on the top management level and by statisticians Six Sigma is used at all levels of the organization that it’ll be implement in. There is still hierarchy of the methodology and who does what.

Three main differences Six Sigma has from other process improvement methodologies:

- It uses two disciplined approaches:

- DMAIC – used to develop/improve existing practice

- DMADV – used to devise/design a defect-free procedure

- Uses varied numerical and problem solving techniques and tools

- Is being run by a trained and certified professional (Black Belt) and guided by a Master Black Belt

Six Sigma uses a collection of numerical and problem solving techniques and tools taken from Kaizen, Total Quality Management, and Lean Manufacturing. Each tool is associated with a particular phase/stage of the DMAIC/DMADV approach.

Six Sigma Project Hierarchy

The Six Sigma project starts in forming the Six Sigma organization. The roles and responsibilities of each member should be clearly defined. Here is a sample of defined roles and responsibilities:

- Leader/Leadership Council – senior-rank management who is accountable for executing Six Sigma project within the association

- Champion – performance head in-charge with directing and enlivening the Six Sigma efforts

- Finance Representative – substantiate projected and concrete savings

- Project Sponsor – senior-rank management who funds the Six Sigma projects and has directorial power to modify changes in the process

- Process Owner – a certified person accountable for the business course of action that is the target of Six Sigma project

- Coach – gives technical help and support to the project group

- Team Leader – also identified as the Project Head, responsible in organizing the Six Sigma projects from launch to finish

- Master Black Belt – a highly practiced Black Belt who has supervised numerous projects and is a specialist in Six Sigma techniques and methods. Person accountable for training and mentoring Black Belts and for assisting the Six Sigma Champions and Head.

- Black Belt – permanent expert who acts as a team lead on Six Sigma assignments. Usually has four to six weeks of classroom education in methods, numerical tools, and team proficiency

- Green Belt – trained person who plays a part-time role on a Black Belt project team or leads less significant assignment. Usually has three weeks of classroom education in methods and basic numerical tools

- Yellow Belt – usually has one to two weeks classroom education. Devotes part-time work while doing the usual work duties

The Six Sigma Team

Ideally, team size should be between five and eight. In bigger industries they require more than the ideal team size. Team members should be carefully selected. Some factors to consider in selecting team members are:

- should have the best knowledge of the procedure being improved and those who can or have contact with customers.

- has the most understanding about the problem, and/or one who have access to the required data.

- should be skillful and has the perspectives needed throughout the course of the assignment.

- it’s also preferred that he or she comes from the department which is mostly involved in the project.

The Roadmap

Once project owners are identified, creation of the roadmap starts. It could either be the DMAIC or the DMADV approach. Regardless which method you use, a typical Six Sigma roadmap has five stages:

- Determine core procedure and target customers

- Identify the requirements of the customers

- Evaluate the current performance

- Analyze, prioritize, and implement development

- Develop and incorporate the Six Sigma structure

Six Sigma is an intangible work process. It is an evolving workflow and procedures. Insufficient facts and data will only lead to ineffective plan. The key to a successful application is a process mindset, expertise in the techniques and tools that will be used, correct selection of team members, and clearly defined problem and objective.

Six Sigma Certification

Since Six Sigma is dominant to the USA most training and certification services are provided here, but it’s quickly gaining traction in other parts of the world, so today you can get trained and certified virtually anywhere in the world.

Online six sigma training and certification is also gaining a lot of attention. It’s generally cheaper and can be done at a pace you’re comfortable with, but it does lack the benefit of having a real person you could ask for immediate help in answering your questions.

Green and Black Belts can be certified by the Institute of Industrial Engineers and by the American Society for Quality among other options. It’s also possible to get certified within the organization you work in. US Military also has their own certification programs.

As with everything there are some arguably negative sides to Six Sigma

Critics say Six Sigma is really nothing new – it has existed long before the term was ever coined. The other controversial aspect is the over-hyped and over-priced consultants. Some argue that Six Sigma does not result in any new breakthroughs in the manufacturing process and thus it can only somewhat improve an existing process but not add anything new or revolutionary to it that could potentially have much higher impacts on the company’s bottom line.

Six Sigma is mainly applied to larger organizations. Preferably ones with more than five hundred employees. Smaller ones will not achieve any significant results from implementation of the methodology and could actually end up losing money on the initiative. This is due to the serious infrastructural requirements and since the improvement will result in relatively small effects. While a big corporation can save very huge amounts of profits. Take for example GE whose announcements in 1998 of $350 millions saved made a huge wave for implementing Six Sigma.