Competition is increased in manufacturing sector because of global business scenario. Innovative manufacturing concepts should be implemented by management of manufacturing industries in order to defeat competitor.

Several benefits such as reduction in setup time, reduction in work in progress, reduction in material handling cost and time, reduction in material flow distance, improvement in machine utilization, reduction in production lead time, improvement in quality, better worker morale can be achieved by adopting cellular manufacturing.

If manufacturer reorganize the cell layout designs every time in order to satisfy the changed requirements then doing so may become time consuming and expensive. Furthermore, if requirements change very often then reconfiguration of cell layout designs becomes impractical or even impossible. It is advisable to implement job shop layout combined with the advantages of cellular layout in such situations.

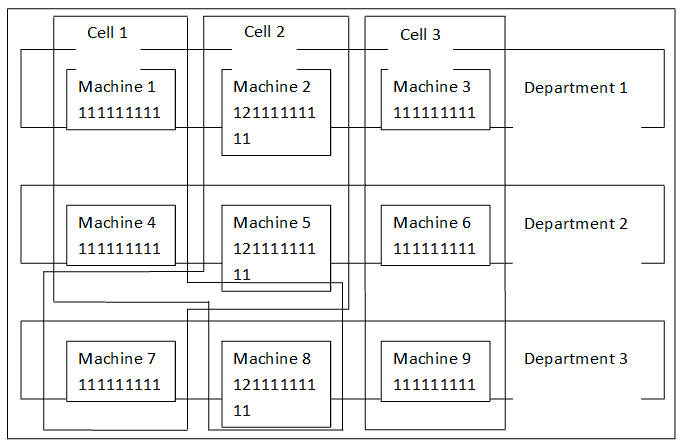

Virtual cellular manufacturing as shown in figure 1 is a novel concept of cellular manufacturing which uses existing job shop layout and combines the advantages of cellular layout with it. Virtual cellular manufacturing is implemented without physically reorganizing existing manufacturing layouts. It virtually creates different manufacturing cells based on operational sequences of various parts.

Thus virtual cellular manufacturing can be implemented to satisfy the changed needs of customers with almost no cost of manufacturing plant layout change. Some manufacturing policy can be used for scheduling the families of parts in order to successfully implement virtual cellular manufacturing system.

Figure 1: Virtual cellular manufacturing

The grouping of parts into part families and machines into virtual cells is presented in table 1. Three virtual cells are created in figure 1:

- Virtual cell 1 contains machine 1, machine 4 and machine 8.

- Virtual cell 2 contains machine 2, machine 5 and machine 7.

- And virtual cell 3 contains machine 3, machine 6 and machine 9.

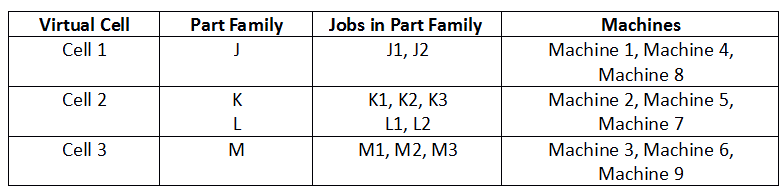

As shown in table 1:

- J1 and J2 are job codes in J type part family which is processed within cell 1.

- K1, K2 and K3 are job codes in K type part family which is processed within cell 2.

- L1 and L2 are job codes in L type part family which is processed within cell 2.

- M1, M2 and M3 are job codes in M type part family which is processed within cell 3.

Table 1: Grouping of parts into part families and machines into virtual cells

Scheduling of part families and operational sequences of parts determine the formation of virtual cells. In virtual cellular manufacturing, machines are not permanently dedicated to virtual cells because when a machine has completed its tasks within current cell and thus it is no longer needed within current cell then it can also be used in the creation of another virtual cell for other part families.

Past research shows that performance of job shop manufacturing system can be improved by forming virtual cells. Average waiting time and set up time of job shop manufacturing system can be reduced by applying the novel concept of virtual cellular manufacturing. Thus virtual cellular manufacturing can be utilized to reduce waiting time, set up time, production lead time and to improve manufacturing productivity.