Throughput yield is an important concept in Six Sigma that measures the efficiency of a process. It is a universal and standard metric that can be used for processes of any nature. Thus it enables different processes to be compared on a level ground.

It measures the inherent ability of a process to meet the specifications or otherwise the ability to process units without defects. It uses defects per unit as its base.

To understand the concept of Throughput yield, you need to first understand the calculation of Yield. Yield is the ratio of number of acceptable units after production over number of units that enters production.

This calculation does not take into account the rework considered and thus is not a true measure.

Therefore, another metric First pass yield was used.

But even this lacked perfection. Both the above metrics use defective as their base measure. Chances are that there could be more defects in a single defective unit. Until this is taken care Yield or First Pass Yield is not a true measure of efficiency of the product.

Throughput yield is based on the defects. It uses DPU (Defects per unit) for its calculation.

Thus Throughput yield is an effective way of measuring the success rate of process.

Normally there are multiple processes that together deliver a final product. These processes may be placed in row or operate parallel and deliver output to a single process. To calculate the overall Throughput yield of the processes, a concept called Rolled Throughput Yield is used.

The formula for calculating Rolled Throughput Yield differs for parallel process and a serial process.

- RTY for a serial process is calculated by multiplying the TPY of all the individual processes.

- RTY for a parallel process is the minimum of all the individual processes operating parallel.

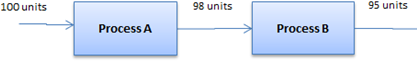

Rolled Throughput Yield For a Serial Process

Assume the below assembly line process:

Processes A, B and C operate in series.

DPUA = 2/100 = 0.02; TPYA = e-.02 = 0.98

DPUB = 3/98 = 0.031; TPYB = e-.031 = 0.969

Therefore RTY = 0.98 X 0.969 = 0.949

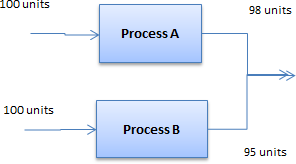

Rolled Throughput Yield For a Parallel Process

Assume that the above processes are performed parallel:

DPUA = 2/100 = 0.02; TPYA = e-.02 = 0.98

DPUB = 5/100 = 0.05; TPYB = e-.05 = 0.95

Therefore RTY = min (0.98, 0.95) = 0.95

The above examples give you an overview of how Throughput Yield and Rolled Throughput Yield are calculated and how these calculations to measure the efficiency of a process.