In the field of Quality management and manufacturing industry, Taguchi’s Quality loss function proposed a different approach and was a turning point in how businesses considered cost of quality and loss associated with poor quality product.

Let us have a look at the traditional quality loss approach and the Taguchi model.

Traditional Quality Loss:

- Traditionally organizations had specification limits: Upper or Lower specification limits or sometimes both limits. All values of the product characteristic that falls within the limits are considered acceptable and are considered equal irrespective of where the value lies within the range and the variation of the characteristic.

- Also, while measuring the loss, the cost of poor quality was measured only till the product was sold to the customer. However, in real scenarios, the cost of poor quality was manifold than the production cost of the product cost itself, which was not estimated as COPQ.

Taguchi’s Loss Function:

Taguchi countered both the assumptions of the traditional approach. He stated that:

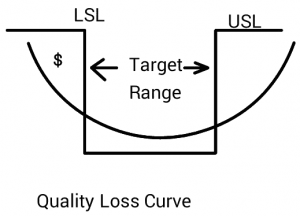

- Not all values falling within the specification limits are equal and create equal loss due to poor quality. The loss value depends on how close the characteristic is to the targeted value.

- Quality Loss is not only the cost spent on poor quality till manufacturing. It includes the financial loss to the society. He proposed a Quadratic function to explain this loss as a function of the variability of the quality characteristic and the process capability.

He explained that the loss value is a function of the process capability; because, process capability represents how consistent the Quality parameter is and how close the parameter’s performance value lies to the targeted value/average value.

Therefore processes with less variation will have a lower cost of poor Quality. Thus Taguchi explained that variation directly affects the Quality and hence Customer satisfaction and Revenue of an organization.