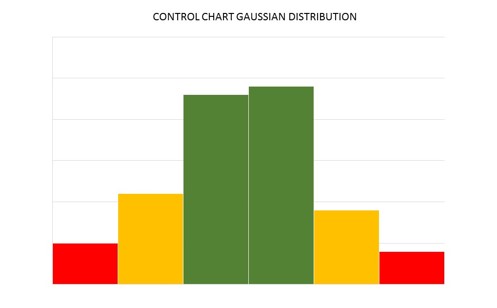

Special Cause Variation, is a process anomaly that is induced by an unpredictable event. The image above depicts a Gaussian distribution, which depicts a natural distribution of points about a mean. When a process is operating normally, the curve above is the anticipated distribution of any critical process parameter that is under control.

When process control analysts witness such a trend, there is joy, for the process is stable. From a controls perspective, all that is primarily desired is for the system to be in control and capable. Variability is the enemy of quality.

Anticipated process variations are attributed to expected process changes. Every now and then, an unexpected variation will occur that will cause an unanticipated adverse effect. The perfect example of a special cause variation is in the case of the failure of the SpaceX Falcon Heavy Rocket’s Center Core.

Anticipated process variations are attributed to expected process changes. Every now and then, an unexpected variation will occur that will cause an unanticipated adverse effect. The perfect example of a special cause variation is in the case of the failure of the SpaceX Falcon Heavy Rocket’s Center Core.

The SpaceX Falcon Heavy Rocket is the largest rocket to have left United States Territory since the late nineteen seventies. The SpaceX organization is on a mission to facilitate cheaper space exploration. Over time, they have been optimizing their rockets via improved designs. The organization started off via developing their Falcon 9 rockets, which consist of a base with nine merlin 1D engines. Loaded on top of the Falcon 9 is the standard payload, which is deployed once the rocket is in Lower Earth Orbit via a smaller Merlin vacuum engine.

Typical SpaceX flights, when observed, follow standard operating procedures. You can literally time with seconds precision, when blast off occurs, when main engines cut of, when the payload is deployed, and when the rocket cores return to Earth to land. It’s an interesting phenomenon to observe but it came via years of iteration. The SpaceX optimization process has included a myriad of failures, which the team has identified and tweaked. When a rocket has a failure the cause is often adverse.

The Falcon Heavy Rocket was the fusion of three Falcon 9 rockets. The primary objective of the recent inaugural test flight was to see if it was possible to fly such a large vessel. The two outer Falcon’s acted as boosters, while the center core carried the test payload to space.

As orchestrated, the Falcon Heavy gracefully flew to space. At lower earth orbit, the two side boosted successfully separated from the main core and returned to earth for a spectacular twin landing. The center core which is an identical unit to the other three, wasn’t so lucky. It crashed out at sea during its return to the Earth. The root cause, thanks to process data analysis, was a failure in the landing burn sequence. What caused this failure still hasn’t been revealed. This anomalous factor is what we call “Special Cause Variation”. It is random and unexpected.

The ingenious design of the Falcon Heavy Rockets is that the 9 Merlin 1 D engines throttle the unit through each stage of the flight and act as both engine and brakes. During blast off, all engines are in operation to facilitate the overcoming of the Earth’s gravitational field. Once in space, the engines cut off, and the rockets are drawn back to the Earth, where the gravitational field pulls the vessels towards it.

Where gravity acts, there’s acceleration, so the rockets are designed for controlled descent by ignition of three of the 9 engines. The generated exhaust gases create enough upthrust for a gentle landing. For the Falcon Heavy Center Core, only one Merlin 1 D Engine ignited during descent, and the unit accelerated to the Earth faster than anticipated and crashed out at sea. Why the other two engines didn’t ignite, is still under investigation. One rocket costs approximately $60 million dollars so the loss was relatively significant.

A detailed root cause analysis will be executed in order to identify what caused this abnormal occurrence, but it is clearly an observation that will have to be made and rectified before the units can be manned in the future. The rocket designers will think through each possibility on their quest to return their systems to normalcy.