Job shops are designed to manufacture a wide variety of products with small lot sizes in order to achieve maximum flexibility. Products have usually different operation sequences and operating time for each operation could vary significantly in job shop manufacturing. Products are released to the job shops in batches also called jobs.

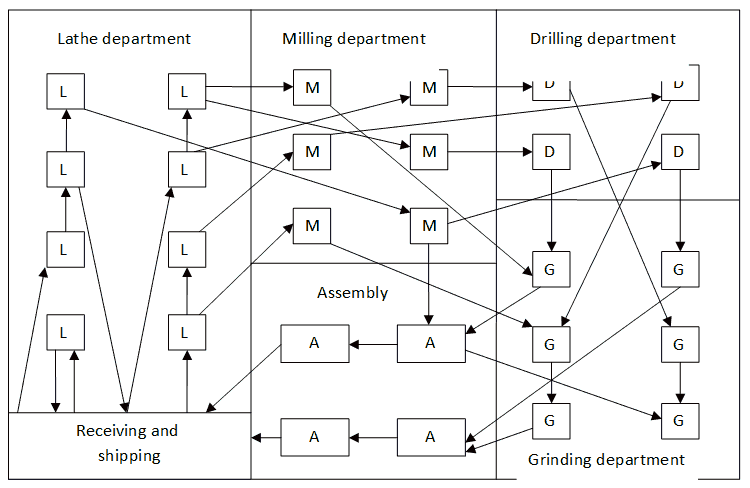

General purpose machines are suitable in job shops because they are capable of performing many different types of operations and thus capable of producing a wide variety of products with small lot sizes. Machines which perform similar function grouped together: lathe machines in one department, milling machines in another department and so forth. Job shop manufacturing is shown in figure 1. A job shop layout is also called a process or functional layout.

Figure 1: Job shop manufacturing

Advantages of job shop manufacturing

1. Better utilization of machines

In job shop manufacturing, all machines are fully and effectively utilized thus fewer machines are required to manufacture a wide variety of products. Thus job shop manufacturing needs lower investment because of comparatively less number of machines. Also purchasing cost of general purpose machines becomes lower.

2. Greater flexibility

Both a varied quantity and a varied mix of products can be manufactured because there are

not dedicated machines. This leads to greater flexibility in job shop manufacturing.

3. More effective supervision

As the machines are grouped into departments on the basis of functions performed by them, the specialized knowledge of supervisors about their departments ensures the specialized and more effective supervision. Supervision task becomes more effective because each supervisor has to supervise limited same types of machines functioning in his/her department.

4. Develop high skills & knowledge in operators

Each operator is working in a single department. This develops high skills and knowledge in operators to perform various tasks in their departments. Management can also take advantages of capabilities of operators in order to execute manufacturing activities more effectively and efficiently in each department.

Disadvantages of job shop manufacturing

1. High material handling cost

Material/parts must be moved from one department to another department. If machine in another department is not ready to accept a job or worker is unavailable then materials need to be stored and protected there. Status & location of materials are difficult to track and control. Thus cost of moving, storing, protecting and controlling materials becomes high in job shop manufacturing.

2. High material flow distance

When the processing of a part has been completed in one department in the job shop manufacturing, it usually must be moved to next department travelling a large distance. Material flow distance is high in job shop manufacturing because every parts may have to travel through the entire shop to complete all of the required operations.

3. High production lead time

Each part in a batch must wait for the remaining parts in its batch to complete processing before it is moved to the next stage of production. This causes high production lead time and low production rates in job shop manufacturing.

4. High levels of work in progress inventory

Level of work in progress inventory is high in job shop manufacturing because of high production lead time.

5. High production cost

A production cost in job shop manufacturing is high because of high material handling cost and high material transportation cost.