‘Heijunka’ as you assumed correctly is a Japanese word. Yes, like most of the Quality concepts it originated in Japan, in The Toyota. The word ‘Heijunka’ means leveling. It is one of the LEAN tools used by manufacturing companies, but can be applied to any operations framework.

The objective of ‘Heijunka’ is to keep up the production lines with the variations and fluctuations in market and customer demand. It functions in both ways: 1) To avoid over-production and piling up inventory which increases the storage cost; 2) To avoid shortage in supply of produced goods on time by keeping an optimum buffer of produced goods.

Since both of these objectives are contradictory to each other, implementing and operating with ‘Heijunka’ on floor consistently is a great challenge to organizations and often require skill, experience and creative thinking to implement new and successful ideas.

To implement ‘Heijunka’ an organization should have a fair ‘Demand Prediction’ system in place, if not perfect. In today’s scenario, a perfect ‘Demand Prediction’ is really tough but completely ignoring it can lead to business disasters.

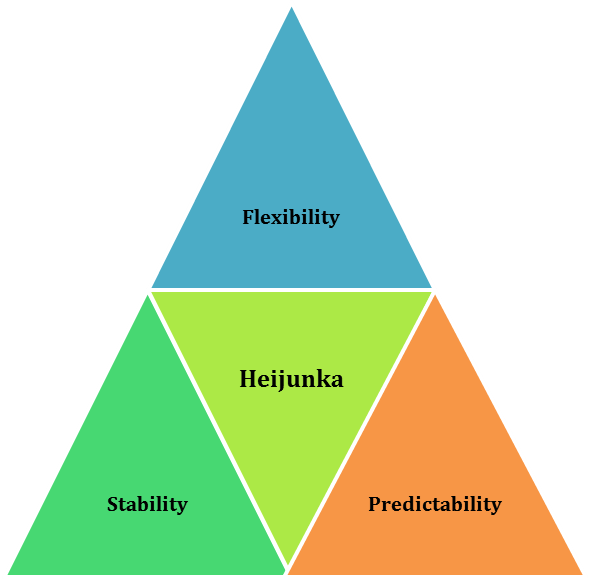

Heijunka depends on the below three ways to achieve its objective. They are:

- Flexibility

- Stability

- Predictability

- Flexibility: In production sequences it is the sharing of an equipment/resource between one or more product/service. The changeover time that a machine takes to switch from manufacturing one product to other is a critical criterion. The faster the machine switches, easier is the production time and changeover.

- Stability: Averaging out the number of products in each type to be produced in every single lot (between change-overs) is also an important criterion. Often the batch size determines the buffer availability and is directly related to product availability.

- Predictability: As we already saw, much required for an organization to devise its schedules, batch sizes and also product type orders in changeover. Moreover, some organizations level up and have tried to do Demand leveling (influencing customer demand by means of product offers, discounts etc)

Thus Heijunka tries to level the volume and types of products to meet customer demand, without keeping too much inventory.