As already described, Design of Experiments or short DoE is a process of designing experiments to understand and validate the relationship between a list of input factors and a desired output variable.

The article on DoE has already explained the importance and benefits of DoE, key terminologies like error, noise factors, correlation and interaction. This article will provide information that will be helpful to successfully plan a DoE.

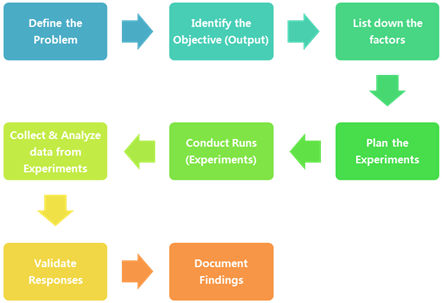

The process of DoE has the following steps. We will look at details to be taken care at each step to successfully conduct a DoE.

The main purpose of Planning & Designing Experiments is to obtain maximum amount of information from a least or optimal number of experiments (runs) & trials.

Pre-Requisites of a DoE Planning

One must note the below points before designing & conducting Experiments.

- Define the Problem: One must confirm whether a DoE is really needed for the problem taken. One should evaluate whether the required result or information can be obtained from any other source, or any set of calculations. There may be constraints in availability of raw materials & equipment. Some experiments may be very costly and time consuming. Therefore, DoE must be chosen when it is absolutely necessary and there are no other alternatives available.

-

Identify the objective of the study: There may be different objectives.

- Exhaustive Study: One might need to know the complete list of variables/factors affecting the response variable. For this, a full factorial design is needed. No factors or levels should be omitted while conducting experiments.

- Examine Specific factors: Sometimes, the business need will be to only validate the effect of a single or few parameters on the response variable. For this purpose, there is no need to conduct all the experiments.

- Screening: The business need might be to identify only the vital few variables that have the maximum impact on response variable. One must study the Signal to Noise ratio, trivial factors that are not needed.

The number and set of experiments and trials will vary depending on the requirement. One must first ascertain the objective of the study to choose the appropriate design.

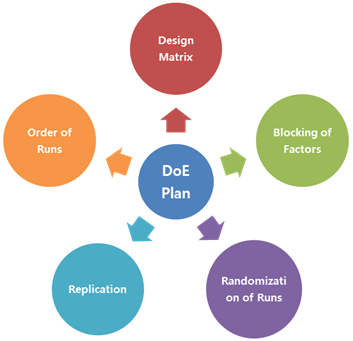

While planning and designing experiments the below items should be considered.

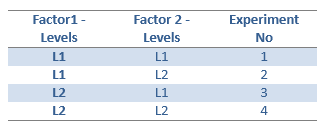

- First use a Design Matrix to identify all possible combinations of factors and levels. The Design matrix will help to identify all combinations and an experiment will be conducted for each row item.

The above table illustrates a Design matrix for a design that has two factors with two levels each. Each Factor-level combination has a unique experimental setup, which is called a Run. At a minimum, one experiment should be conducted per run.

- Blocking of Variables/Factors: While organizing experiments, runs can be grouped in a specific order for the ease of conducting experiments. Runs with factors that are homogenous to each other are grouped as clusters and experiments may be conducted together or sequentially or combined, depending on the nature of variables. This process of grouping runs based on the behavior of factors is called as Blocking. One should look at opportunities for blocking to reduce time and effort. Blocking is also used to screen the effect of known sources of variation.

- Randomization of Runs: It is known that there are interactions between factors which create a combined effect on the output variable. In addition to this, there may be some uncontrollable influences like change in equipment, raw material etc. To reduce the effect of these uncontrollable influences, the experiments should be conducted in no particular order but random, so that the effects are minimized.

- Replication of Runs: Replication or repetition of experiments is done to dampen the effect of uncontrollable variation. Also it helps in acquiring precise estimation of response and to detect the S/N (Signal to Noise) ratio better. The number of trials depends on the precision of equipment. Therefore, it is necessary to conduct MSA before conducting DoE.

- Order of Experiments: Experiments can be conducted either sequentially or in parallel. Sequential approach is required, when the outcome of one experiment is required to modify the set-up of further experiments. Otherwise, if there is enough equipment and manpower, Parallel runs will reduce the time spent on conducting experiments.

The above points will help in designing a perfect DoE plan that optimizes the number of runs and maximizes the data and information collected to meet the objective of the study.