One methodical tool used in Six Sigma that is very effective in validating the correlation between input variables and output variables is the Design of Experiments or DOE. The name itself states its definition – designing an experiment so that once conducted it gives reliable data and you won’t have to conduct it again due to an error in the process of experimenting. It consists of several experimental processes that are used to calculate undetermined measurements of causes and the connections between these causes. For further reading see our article on Planning your DoE.

It’s done statistically throughout the execution of mandatory changes that is logically managed by mathematically methodical charts. The implementation of changes within the organization results in unexpected and sometimes unfavorable outcomes. Thus, further analysis is required otherwise the organization will suffer.

DOE is a methodical approach that will investigate the current process or system. Sequence of prearranged experiments is designed to which intended changes are placed to the input factors of the system or process. The outcome of these intended changes on the pre-identified output is then evaluated. The method uses not just one set of experimental concepts but more depending on what the project owners want to establish.

Most of the time it is the work of the Black Belt to choose which project concept should apply to the analysis. The difference of DOE from other Six Sigma tools is that the input variables are manipulated and it’s the outputs that are being measured and studied. Other Six Sigma tools measure both input and output factors.

There are so many designs used to measure and determine the impact of each input. Project owners may use the full factorial scheme, or the fractional factorial model, or the response surface design.

The full factorial scheme analyzes the impact of every input or mixture of inputs to performance. Response surface and fractional factorial on the other hand uses definite algorithms to minimize the occurrence of iterations essential to achieve favorable results.

DOE is mostly used on projects with insufficient data. In the Analyze phase it is used to validate possible defects. This is done by showing if there is change in performance and if the supposed caused is changed. In the Improve phase, DOE is used to confirm if the designed developments will give the anticipated outcome. DOE is also capable of determining which design concept can give the best result.

Since DOE is commonly used when there is inadequate data, it maximizes the available information. Most methodical techniques offer results that promote either a single change done at one time or a combination of changes done at the same time, both of which have their own limitations.

A single change done at one time is time consuming and may not be cost-efficient. A combination of changes done at the same time on the other hand may give more unfavorable results rather than a favorable outcome. Since there are several changes made, effects might be greater than expected. Using DOE, the project will be ready for all potential dependencies by recommending the required data that needs to be evaluated.

DOE is also best used to answer questions such as: “what factor contributes most to the problem?”, “what is the most excellent arrangement of aspect values to reduce dissimilarity in response?”, “how far can the process work if there is noise involved?” Most questions seek for the effectiveness and strength of the design.

There are several intentions on why DOE is used. It could either be to compare alternatives, to determine significant inputs that affect output, accomplishing the most favorable output, minimizing variability, minimizing and maximizing responses, developing the product or process robustness, and harmonizing tradeoffs.

It is a must that you have basic understanding in statistics for you to perform the experiment. Understanding the components of an experimental concept is also a must. You should be able to understand what are the input (factors), setting (levels), and output (responses) that should be measured.

The factors or also referred to as the input can be categorized as either uncontrollable or controllable. The response of the experiment may vary depending on their respective factors. Important responses are calculated and evaluated to identify the factors and their levels that will present the most excellent overall response for the CTQ characteristics – both should have variables that are measurable and attributes that are assessable.

Every experiment has stipulating guidelines: the factors (input) to be evaluated, the levels (setting) of these factors, and the structure or conditions of experimental trials. Two things to keep in mind when doing experiments, they should be very simple and cost-effective. Two more conditions also should be considered: (1) measurement system should be capable, and (2) process should be stable.

Deficiency on either condition will result in unreliable response. Dissimilarity impacting the output must be restricted to random error causes and not those that are caused by specific actions. Difficulties and complexities are always present when creating experiments. General rule is – the simpler the experiment is the better.

Here are some experimental difficulties that you might encounter and should stay away from:

- Error – could either be a measurement error or error on sources or inexplicable variation, these can greatly obscure the response. Error is referred to inexplicable variation either on the experiment trial or between experiment trials. Experiments that are accurately designed can easily determine and calculate the cause of errors.

- Noise factors – these are uncontrollable inputs that stimulate variation even when under the usual operating condition. Examples of this are raw materials, numerous machineries, multiple shifts, and humidity. A strong feature of DOE is that it is capable of determining the inputs and levels that reduces the effects of unmanageable factors.

- Correlation – referred to as the relationship between two factors, correlation and causation are often confused. There may have instances where two different factors maybe well correlated devoid of one causing another factor. The root of the cause could be due to another third factor. Data analysis that lacks operational knowledge could result to false conclusion. It is best to involve people, who are from the affected environment, in the brainstorming activity.

- Interaction – also called the combined effects. Factors could result in non-linear effects that do not add value.

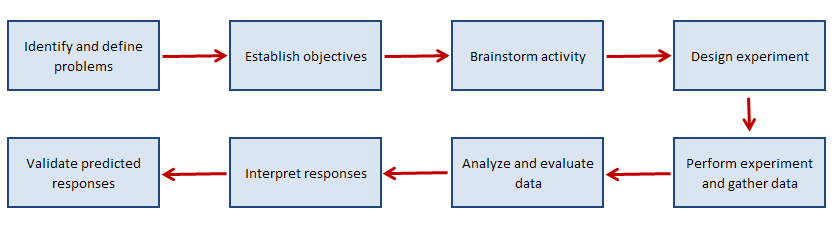

Here is an example of DOE flowchart:

Design of Experiments (DOE) Flowchart Example

DOE’s advantage over other systematic techniques is that it allows project owners to select which design has the utmost impact on the process or product. It is also capable of solving long-standing and intricate problems in segments. DOE also is the best tool to identify which amongst the various factors of a complex process gives the biggest impact.