Three problems namely:

- cell formation problem,

- machine layout problem and

- cell layout problem

require to be efficiently and optimally solved to implement cellular manufacturing system successfully.

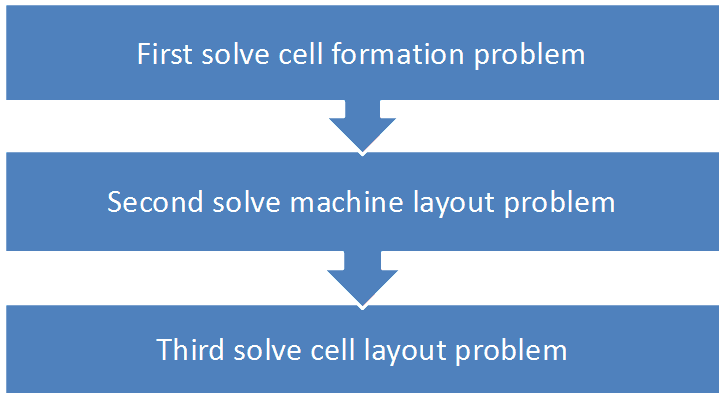

These problems shown in figure 1 are called cellular manufacturing system problems and are described as per the following.

Figure 1: Cellular manufacturing system problems

Cell formation problem:

Solving cell formation problem is the first step toward implementation of cellular manufacturing system. Objective of cell formation problem is to group parts with similar design features or processing requirements into part families and the corresponding machines into machine cells. This process of grouping should maximize grouping efficiency and grouping efficacy.

Machine layout problem:

Solving machine layout problem is the second step toward implementation of cellular manufacturing system. Consider m machines and p parts. Single machine processes various parts and it may often be utilized during the manufacturing of a variety of different products. Different parts may have different operational sequences and different demands. Objective of machine layout problem is to minimize total traveling distance of all p parts by determining an optimal layout scheme of all m machines subject to no overlap and no duplication of machine constraints.

Cell layout problem:

Solving cell layout problem is the third step toward implementation of cellular manufacturing system. Objective is to determine an optimal layout scheme of all cells within the factory or shop floor in a way that minimize inter-cell movement of various parts.

Solving sequence

Cell formation problem, machine layout problem and cell layout problem should be sequentially, efficiently and optimally solved in order to optimize the performance of industrial manufacturing processes, to reduce total manufacturing cost, time and area and to improve profit, productivity and production quality.

Cell formation problem has been solved by most of the researchers, many researchers have solved only machine layout problem without first solving cell formation problem while only few researches have solved cell layout problem & these three problems completely.

Cell formation problem, machine layout problem and cell layout problem should be sequentially solved in order to generate complete cellular manufacturing system design. Cell formation problem, machine layout problem and cell layout problem have been concurrently solved by some researchers by developing single approach. Concurrently solving two or more problems may waste computational time, may not find out optimum design of cellular manufacturing system and thus solving two or more problems concurrently is not advisable.

Solving methods

Heuristics, meta-heuristics, hybrid methods and exact solution methods may be used to solve cell formation problem, machine layout problem and cell layout problem. Genetic algorithm based approaches are most popular and widely used by most researchers to solve cellular manufacturing system problems.

Performance of genetic algorithm can still be improved by choosing proper components and suitable value of parameters in implementation of genetic algorithm. Exact solution methods find out optimum solution of cellular manufacturing system problems but they consume much more time to find out the solution of cellular manufacturing system problems compared to heuristics, meta-heuristics and hybrid methods.

Exact solution methods are recommended to solve small-sized and medium-sized cellular manufacturing system problems. Exact solution methods may fail to find out the solution of large-sized cellular manufacturing system problems due to hardware limitation.

Heuristics, meta-heuristics and hybrid methods can solve large-sized cellular manufacturing system problems efficiently in such situations where exact solution methods fail to obtain the solution of cellular manufacturing system problems in a practical length of time but heuristics, meta-heuristics and hybrid methods may not find out optimum solution of cellular manufacturing system problems. Heuristics, meta-heuristics and hybrid methods are recommended to solve large-sized cellular manufacturing system problems.