1. INTRODUCTION

Assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. Also, the assembly line needs to be designed effectively and tasks needs to be distributed among workers, machines and work stations ensuring that every line segments in the production process can be met within the time frame and available production capacity. Assembly line balancing can also be defined as assigning proper number of workers or machines for each operations of an assembly line so as to meet required production rate with minimum or zero ideal time.

The very purpose of line balancing is to assign workloads to each assigned work station in a manner that the every works stations has approximately same amount of work to be done.

Benefits of Assembly Line Balancing in organization.

- Improved process efficiency

- Increased production rate

- Reduced total processing time

- Minimum or Zero Ideal Time

- Potential increase in profits and decrease in costs

2. ASSEMBLY LINE PROBLEM

Problem: The below product in a factory is assembled in an assembly line. This process needs to be re-arranged to find a balance that minimizes the workstation cycle time.

EXISTING ASSEMBLY LINE

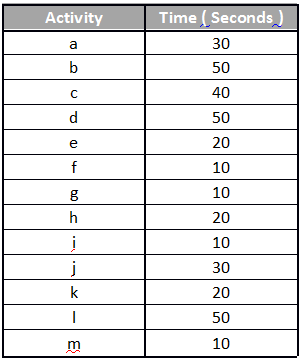

Below is an assembly line showing list of 13 activities that needs to be completed to produce a product. The actual time required to produce each of this activity are as follows.

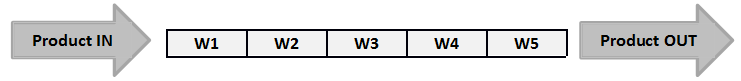

The assembly line has 5 workers (work stations) stationed on the line as follows where back tracking is not allowed.

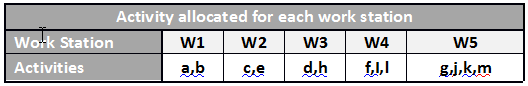

The activities assigned to each workstation by production team are as follows.

NUMBER OF WORK STATION:

Number of Workstations (n) = 5

TOTAL PROCESSING TIME

Tp = ? Processing Time of all activities

Tp = 30 + 50 + 40 + 50 + 20 + 20 +10 +10 + 10 + 20 + 30 + 50 + 10

Tp = 350 Seconds

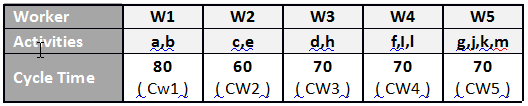

CYCLE TIME OF EACH WORK STATION

CYCLE TIME OF ASSEMBLY LINE

Cycle time of Assembly Line is the maximum time of individual work stations.

CL = Maximum (CW1, CW2, CW3, CW4, CW5)

CL = Maximum (80, 60, 70, 70, 70)

CL = 80 Seconds

BALANCE DELAY

Balance delay indicates the ideal time on the assembly line.

Balance Delay (DL) = (nCL – Tp)/ nCL X 100

DL = [(5 X 80) – 350] / [5 X 80] X 100

DL = 12.5%

PRODUCTION RATE

Assuming Production happens 24 Hrs in 3 shifts each of 8 hrs.

Production rate (PL) = Available Time / Cycle Time

PL = (24 X 60 X 60)/ 80

PL = 1,080 Units

Hence with existing assembly line, 1080 units can be produced per day.

REARRANGEMENT FOR BETTER BALANCE

Total Number of Workstations ( n ) = 5

Total Processing Time ( Tp ) = 350 Seconds

Average Time per work stations = Tp/ n = 350/5 = 70 Seconds

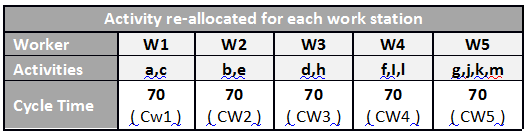

Following rearrangement was done, so that each station could be allocated 70 seconds.

CYCLE TIME OF ASSEMBLY LINE (CL) = 70 Seconds

BALANCED DELAY (DL) = 0, Balance delay is Nil.

PRODUCTION RATE

Production rate (PL) = Available Time / Cycle Time

PL = (24 X 60 X 60)/ 70

PL = 1,234 Units

Hence with new assembly line, 1234 units can be produced per day.

Increase in Production = 1234 – 1080 = 151 Units.

Percentage Increase in Production = (151/ 1080) X 100 = 14%

3. CONCLUSION

In the above example we could clearly understand that with proper arrangement and allocation of activities and tasks to individual workstations in assembly, we could increase production by 14%. In the manufacturing industry it is always necessary to re-arrange the activities based on individual workstations so that the total processing time can be optimized and the effort – well balanced, leading to optimum level of production.