A Quality Management System is a set of processes defined and implemented to enable an organization to satisfy the needs of its customers. It is a defined and documented approach that guides all levels of management, all departments of an organization as well as all suppliers of the organization in marching towards a common goal – Understanding Customer needs and requirements and delivering products and services that caters their needs.

Now, to understand and use the concept of QMS in our business and operations, let us explore the below areas:

- What is the purpose of Quality Management System?

- What are the elements of an effective Quality Management System?

- What are its benefits?

- What types of businesses and organizations need a Quality Management System?

- Are ISO 9001 and QMS one and the same?

Let’s discuss these questions one by one…

What is the purpose of QMS?

My organization has a Quality team that takes care of all Quality related activities. Do I really need to have a QMS?

Yes, irrespective of whether a company has an inbuilt Quality team or not, QMS is a must for all organizations that want to deliver and excel in satisfying the needs of their customers.

QMS is not limited to activities performed by a Quality team. In fact, your Quality team’s activities are only a meager percentage of items that are a part of QMS. A huge chunk of it is executed by different processes and functions. As discussed already, QMS is attributed to all departments of an organization and extends to suppliers also. The Quality team enables and supports successful deployment of QMS in an organization. QMS is a tool and the Quality team is a driver that uses the tool for the betterment of the organization

What are the elements of an effective QMS?

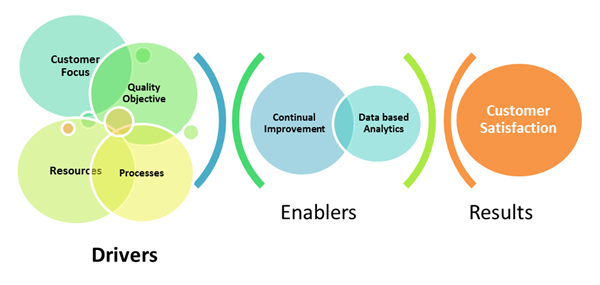

From the definition of QMS, we can derive the QMS elements easily. The objective of QMS is to deliver and satisfy customer needs. Therefore, Customer Focus is an integral part of any QMS. To work towards this goal, any organization will have a Vision, Mission and Quality objective. This will be the next element of a QMS. To achieve this goal, the organization will devise processes, policies for various departments.

Then the organization will allocate resources for the processes to be executed. Next, to ensure that these processes do not have any bottlenecks and resources are utilized effectively, the organization will use Data based analytical approach and continual improvement process. Thus, the above highlighted items are the integral part of an effective QMS.

Apart from this, a Quality Manual (A document that describes how an organization is going to handle all these elements) is also a main part of QMS. A Quality Manual has:

- Quality Policy

- Processes and their descriptions

- Resources that are to be used

- Product/service that needs to be delivered

- Approach for Continual improvement

- Records and documents that needs to be documented and managed

- Auditing mechanism for compliance to QMS

- Approach for data based analysis and process correction

What are the benefits of using a QMS?

- QMS brings a defined approach to achieve the objectives of an organization. Therefore, it provides the management team a clearly defined path that will lead to success.

- It sets a standardized requirement for all functions and departments. Therefore, assessing the process performance or providing them the expectations from the management becomes a simple task

- Implementation of QMS increases the confidence level of the customers on your product/service. Thus the revenue and market share of an organization goes up.

- QMS ensures that the objectives of the organization are linked towards the customer needs and thus creates a perfect value chain

- Implementation of QMS increases the effective use of resources

- It sets clear objectives for each job role and each team, and thus miscommunication and ambiguity in the way of processing is avoided.

- It enables an organization to understand its pain areas, customer complaints and concerns, and work towards it.

Thus there are enormous benefits in devising a robust QMS and implementing it to its full extent.

What types of organizations can use QMS?

Any organization that delivers any kind of product or service for a price can use QMS to ensure that its objective is achieved in a structured manner. Airlines, software companies, Automobile manufacturers, dyeing units, Universities, Government bodies, Airports, super markets and so many organizations use QMS in their daily business.

Are ISO 9001 and QMS the same?

The answer is “Yes” as well as “No”.

Yes because, ISO 9001 is a QMS that is used across the globe by a huge number of organizations. ISO 9001 is a standard developed by ISO (International Organization for Standardization).

No because, ISO is not the only QMS. Organizations can develop their own QMS catering to their business needs. It can include principles from ISO 9001 or adopt the whole of the ISO 9001 standard, or be a totally different QMS. It is up to the organization and its management needs.